Flexible Add-On System for Stand-Up Bag Packages.

UM-Flex.

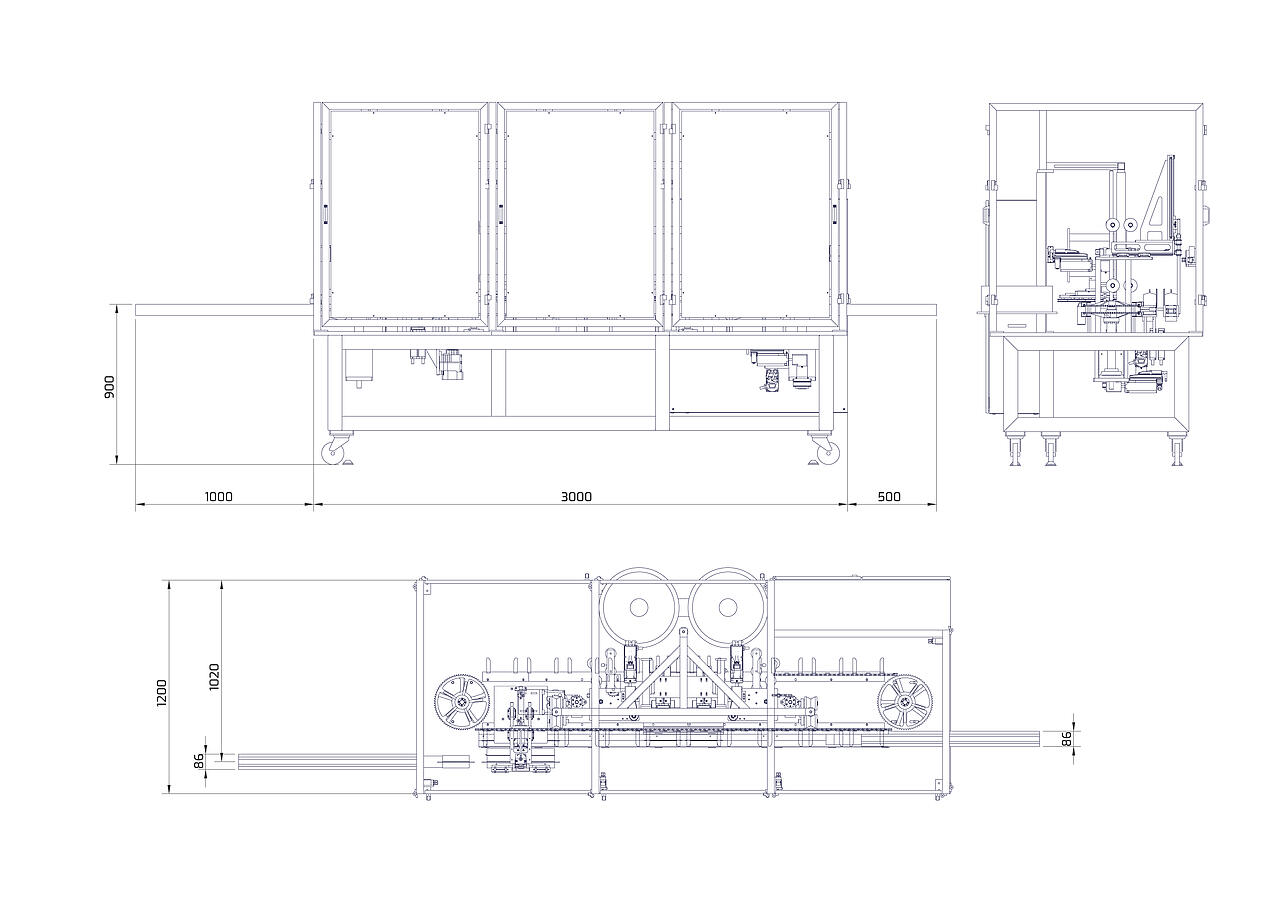

The ULF-Tec UM-Flex may be used for a large variety of tasks: it is used for providing stand-up bags with reclosures, folding the bag top side after closing or applying additional labels. The UM-Flex is provided with rolls and may be used in combination with different bagging machines. Alternatively, the UM-Flex may be designed with an integrated tubular bag machine so that a compact line with maximum flexibility is available.

Products and Fields of Application

- Bags for coffee pads, sweets and cookies

- With integrated tubular bag machine

- Coffee pads in bulks or stacked, noodles, cereals

Types of Bag and Packaging

- Stand-up bags made of sealable film laminates, paper

- Other materials on request

Options and equipment

- Extended bag magazine (max. 2 m, runtime of approx. 35 m without refilling of the bag)

- Data capture systems for production and downtimes

- Film group packers

- Paper packers

- Checkweighers

- Metal detectors

- Modem for remote maintenance

- Maintenance agreements

- Forming trolley for storing a forming set

Basic construction

The UM-Flex rests upon a torsion-free basic frame, holding the drive for the bag transport system and the control. The transport system may be set to different bag widths without much effort and no need of tools and form sets. The drive is realized by means of a servo motor so that the movement of the transport system may be adapted to your products in an optimal way. Depending on your requirements the system may be equipped with different processing stations: starting with simple folding of the top sealed seam with and without fixation over the application of tin ties to the application of additional labels as special marking and/or use as reclosures. Optionally the UM-Flex may be realized as an integrated system in a vertical tubular bag machine. Here the tubular bag machine UM-V-2300 will be integrated into the basic frame so that the bags will be automatically transferred to the transport system after filling and sealing.

Operation

The UM-Flex is operated by means of a 12” touch panel which is swivel-mounted so that the operators are able to control the machine at any time. The access is staggered by password-protected levels so that critical areas are protected. The machine functions may be called and set individually by simple menu navigation to adapt the UM-Flex to the respective requirements of your products and packing materials. If it is not possible to find the correct setting “on site”, you may use the remote maintenance module with many functions. But the control does not only offer the access to machine functions, but also the possibility to evaluate production data.

![[Translate to Englisch:] UM-Flex Auslauf](/fileadmin/_processed_/e/2/csm_UM-Flex_Auslauf-1_800x600_595d688782.jpg)

![[Translate to Englisch:] Um-Flex Bedienpult](/fileadmin/_processed_/e/3/csm_UM-Flex_Bedienpult-1_800x600_c6b206de2d.jpg)

![[Translate to Englisch:] Um-Flex Beuteleinlauf](/fileadmin/_processed_/6/8/csm_UM-Flex_Beuteleinlauf-1_800x600_5cb4808f93.jpg)

![[Translate to Englisch:] Um-Flex Komplettansicht](/fileadmin/_processed_/7/1/csm_UM-Flex_Komplettansicht_II-1_800x600_561fe3c250.jpg)

![[Translate to Englisch:] UM-Flex-Rückansicht](/fileadmin/_processed_/c/9/csm_UM-Flex_Rueckansicht-2_800x600_b0784b37e5.jpg)