The filling line, especially for sugar and other granulates – 20 - 40 bags from 0.5 to 5 kg.

UM40-02V.

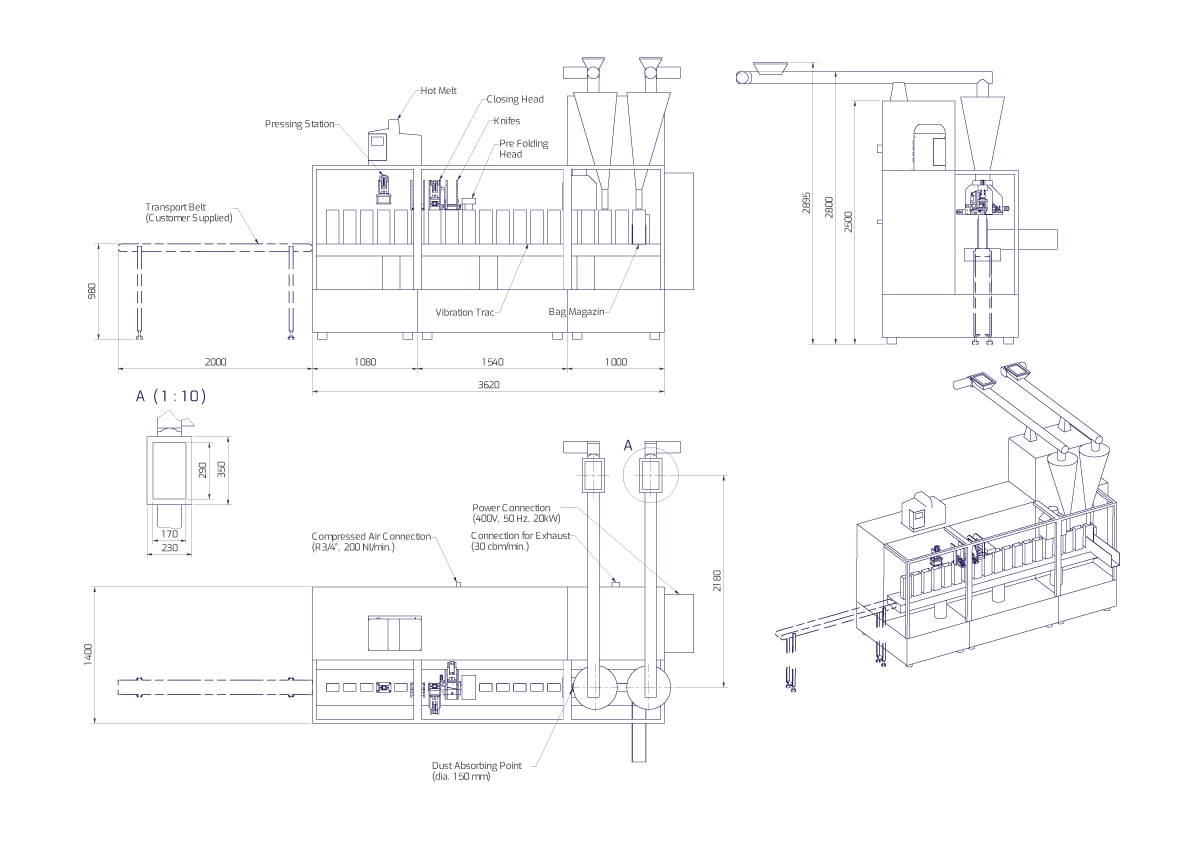

The ULF-Tec UM40-02V is a versatile and resilient filling line with a volume dispenser designed especially for sugar and granular products. It can be used to fill 20 to 40 bags per minute with capacities from 0.5 to 5 kg. The UM40-02V was developed specifically for use under extreme ambient conditions and is correspondingly functional and robust, making it exceptionally long-lasting and resilient. The machine also impresses with its intelligent self-cleaning mechanisms, pneumatic technology, centralised lubrication as standard and reinforced tape gears, shafts and bearings.

Products and Fields of Application

- Filling of dry products (cereals, sugar, flour, pasta, animal feed, granules, etc.)

- Bags for coffee pads can be stacked or in larger quantities

- Confectionery and biscuits

- Machines for pre-fabricated bags

Types of Bag and Packaging

- Sealable stand-up bags

- Suitable for paper packaging and plastic packaging

- Other materials on request

Options and equipment

- Extended bag magazine (max. 2 m, runtime of approx. 35 m without refilling of the bag)

- Data capture systems for production and downtimes

- Film group packers

- Paper packers

- Checkweighers

- Metal detectors

- Modem for remote maintenance

- Maintenance agreements

- Forming trolley for storing a forming set

Basic construction

Flexibility thanks to the modular construction, as well as comprehensive controllability of all processes, are among the greatest strengths of the ULF-Tec Filling Line. The UM40-02V with volume dispenser is made from low-wear aluminium and has a torsion-free base frame. Attached to this frame are the drive for the bag transport system, which makes use of a cam drive, and the control equipment. The easy-to-operate transport system can be set to various bag widths. Various package sizes from 0.5 to 5 kg can also be handled with ease, as can various materials.

The UM40-02V can fill 20 - 40 bags per minute and can, thanks to the volume dispenser and various processing stations, be adjusted perfectly to the customer's specific requirements. These include, for example, the simple folding of bag top edges (with and without securing), fitting of the bags with sheet metal closures or even attaching resealable closures or customised labels and markings. It is also possible to combine this with the vertical, tube-shaped UM-V-2300 bag machine.

The machine components can all be reused in the event of subsequent technical restructuring. Virtually no maintenance or optimisation are required. Should spare parts be needed, these can be ordered quickly and reliably. The integrated Siemens control technology guarantees the best possible functional reliability.

Operation

The UM40-02V rests upon a torsion-free basic frame, holding the drive for the bag transport system and the control. The transport system may be set to different bag widths without much effort and no need of tools and form sets. The drive is realized by means of a servo motor so that the movement of the transport system may be adapted to your products in an optimal way. Depending on your requirements the system may be equipped with different processing stations: starting with simple folding of the top sealed seam with and without fixation over the application of tin ties to the application of additional labels as special marking and/or use as reclosures. Optionally the UM40-02V may be realized as an integrated system in a vertical tubular bag machine. Here the tubular bag machine UM-V-2300 will be integrated into the basic frame so that the bags will be automatically transferred to the transport system after filling and sealing.

![[Translate to Englisch:] UM40](/fileadmin/redaktion/Content-Detailseiten/UM40/_Q7F1256-bearb-2.jpg)

![[Translate to Englisch:] UM40](/fileadmin/redaktion/Content-Detailseiten/UM40/_Q7F1199-bearb-2.jpg)

![[Translate to Englisch:] UM40](/fileadmin/redaktion/Content-Detailseiten/UM40/_Q7F1165-bearb-2.jpg)

![[Translate to Englisch:] UM40](/fileadmin/redaktion/Content-Detailseiten/UM40/_Q7F1106-bearb-2.jpg)