Impressive at 125 bags of up to 3 kg per minute and integrated bag production.

UM120/R.

The UM120/R is one of the most innovative solutions in the packaging line area from ULF-Tec. Its key advantages include the flexible adaptability of the individual work steps to the product requirements, the longevity of all components and the multiple weight checks which are accurate to the gramme. Added to these are the maintenance-free servo motors from Siemens for controlling the transport of paper and glue, the cutting blade, all of the drives for the sheet length and the cut and print image position.

Products and Fields of Application

- Filling of dry products (cereals, sugar, flour, pasta, animal feed, etc.)

Types of Bag and Packaging

- Integrated bag production of pre-printed paper with food-safe cold glue

- Secure shaping of the bags using side folders and vacuum

Options and equipment

- Extended bag magazine (max. 2 m, runtime of approx. 35 m without refilling of the bag)

- Data capture systems for production and downtimes

- Film group packers

- Paper packers

- Checkweighers

- Metal detectors

- Modem for remote maintenance

- Maintenance agreements

- Forming trolley for storing a forming set

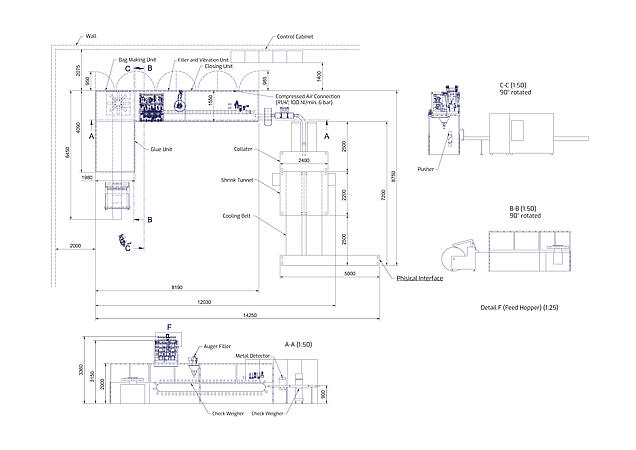

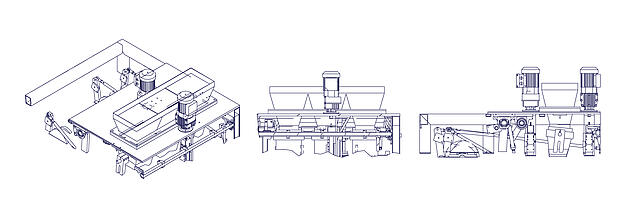

Basic construction

The UM120/R has a torsion-resistant base frame. The transport system offers user-friendly operation and can be adjusted effortlessly. The machine features integrated bag production, allowing three bags to be filled simultaneously thanks to the screw feeder. The filling process is monitored by light barriers and sensors, as well as by an integrated vibrating section and weighing cells. If necessary, top-up dispensing accurate to the gramme is carried out.

Any contamination is identified very effectively by the integrated metal detectors. The bags are folded neatly thanks to pre-creasing and folding heads, while closures are created under sensor control using hot glue.

Thanks to various processing stations, the UM120/R can be adapted flexibly to requirements. These include, for example, the simple folding of bag top edges fitting of the bags with sheet metal closures or even attaching resealable closures or customised labels and markings. The bags are then transported via a sensor-driven points system and two collecting packers for heat sealing.

The machine is built with high quality, it is robust and it is therefore long-lasting. The machine components can all be reused in the event of subsequent technical restructuring. Virtually no maintenance or optimisation are required. Should spare parts be needed, these can be provided quickly and reliably. Added to this are the maintenance-free servo motors from Siemens for controlling the transport of paper and glue, the cutting blade, all of the drives for the sheet length and the cut and print image position.

Operation

The UM120/R is operated via a swivel control panel with a 12-inch touch screen. Multiple password-protected operating levels ensures different, protected intervention options. The system's individual functions, such as the scale check, can be called up using user-friendly menu navigation and set to the product or packaging type required. The control unit is accommodated in a separate control cabinet. A remote maintenance module also ensures the correct operation as well as the analysis of production data.

![[Translate to Englisch:] UM120/R](/fileadmin/_processed_/c/b/csm_FD_IMG_0022_4c_800x600_7dccac6c74.jpg)

![[Translate to Englisch:] UM120/R](/fileadmin/_processed_/4/e/csm_FD_IMG_0082-bearb_800x600_45bc9e2aca.jpg)

![[Translate to Englisch:] UM120/R](/fileadmin/_processed_/f/0/csm_FD_IMG_0066-bearb_800x600_da7e89ca0e.jpg)