The versatile and resilient filling line for product packagings from 0.5 kg to 10 kg and 30 bags per minute.

UM-Ket.

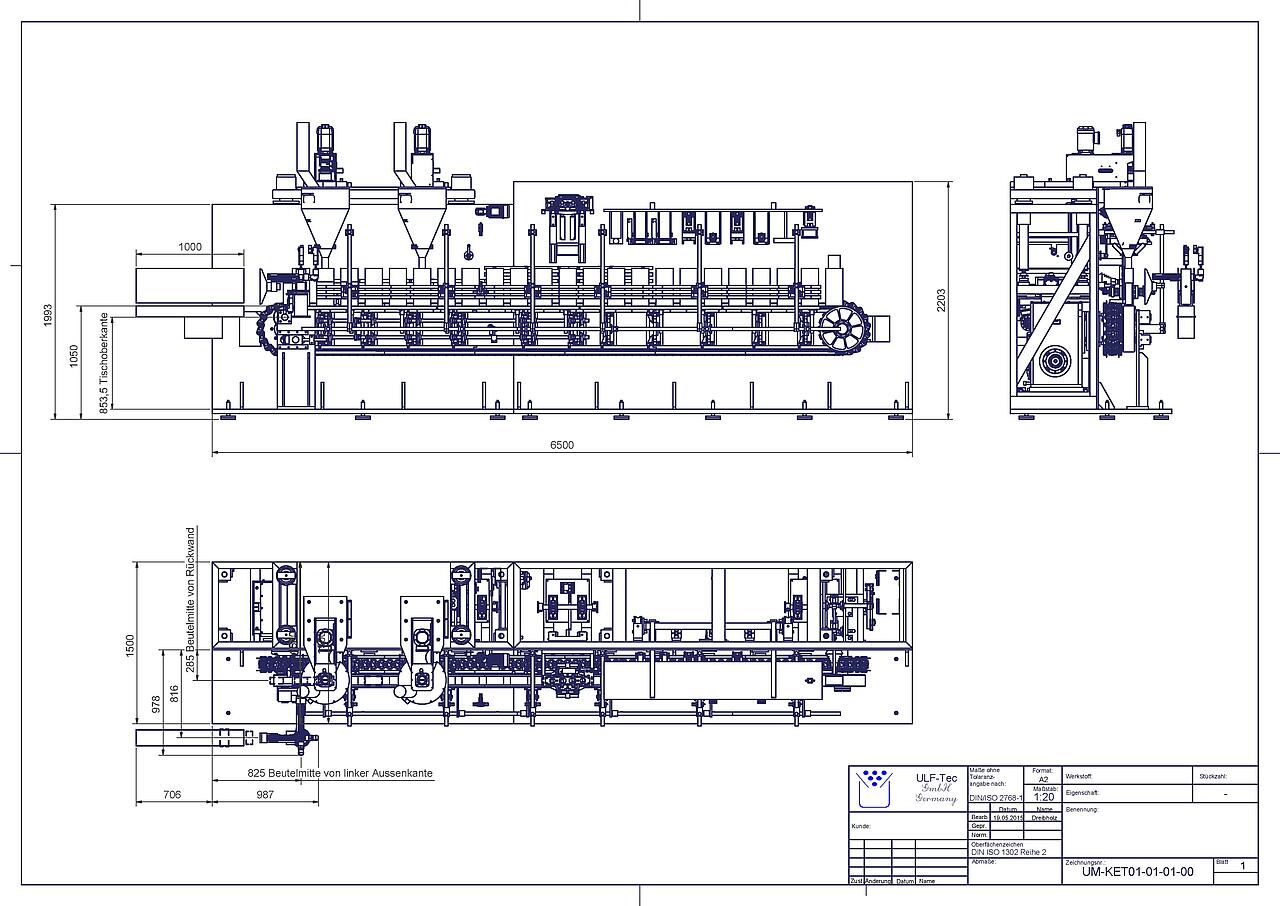

The UM-Ket from ULF-Tec is the result of many years of intensive cooperation with our customers. The UM-Ket has been developed specifically for use under extreme climate conditions. It is reliably functional, gentle on materials, resilient and supports a variety of applications. We use a sturdy, low-wear construction. This makes the UM-Ket especially suitable for products such as construction powder or cat litter, for example. Two dispensers are installed, which can be controlled as required. A change of format can be completed within a sporty 20 minutes. Alongside this, the UM-Ket also impresses with its intelligent self-cleaning mechanisms, pneumatic technology, centralised lubrication as standard and reinforced tape gears, shafts and bearings.

Products and Fields of Application

- Filling of dry products (cereals, sugar, flour, pasta, animal feed, construction powder, cat litter, etc.)

- Machines for pre-fabricated bags

- with integrated tube-shaped bag machine

Types of Bag and Packaging

- Sealable stand-up bags

- Suitable for paper packaging and plastic packaging

- Other materials on request

Options and equipment

- Extended bag magazine (max. 2 m, runtime of approx. 35 m without refilling of the bag)

- Data capture systems for production and downtimes

- Film group packers

- Paper packers

- Checkweighers

- Metal detectors

- Modem for remote maintenance

- Maintenance agreements

- Forming trolley for storing a forming set

Basic construction

The UM-Ket uses a sturdy and low-wear construction. It is built on a torsion-free base frame to which the servo drive for the bag transport system and the control devices are attached. The transport system is simplicity itself to operate and can be adjusted to various bag widths without any tools or moulds. The servo motor ensures flexible adaptation of the drive to the product being handled. Two dispensers are installed, which can be controlled as required.

The UM-Ket can be adapted perfectly to customer-specific requirements with various processing stations. This includes, for example, the use of the different bag materials paper and plastic, the simple folding of bag top edges with or without fastening, the connection of reusable closures or even customised labels and markings.

The machine is built with high quality, it is robust and it is therefore long-lasting. It promises a long-lasting construction. The machine components can all be reused in the event of subsequent technical restructuring. Virtually no maintenance or optimisation are required. Should spare parts be needed, these can be provided quickly and reliably. The control technology comes from Siemens and guarantees the best possible electronic reliability

Operation

The UM-Ket is operated via a swivel control panel with a 12-inch touch screen. User-friendly menu navigation makes it possible to adjust the individual functions of the system to the product or type of packaging in question. The machine has several password-protected operator levels to provide different degrees of intervention protection. The control unit is accommodated in a separate control cabinet. A remote maintenance module also ensures correct operation, as well as the analysis of production data.

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/7/5/csm_UM-Ket_20150925_085239-800x600_b0b33afee2.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/5/f/csm_UM-Ket_CIMG5275-800x600_5cca65882e.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/a/4/csm_UM-Ket_CIMG5322-800x600_a2d919af4b.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/1/b/csm_UM-Ket_CIMG5221-800x600_825bab3cda.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/9/3/csm_UM-Ket_CIMG5190-800x600_9cc43e4d46.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/a/4/csm_UM-Ket_CIMG5267-800x600_7f9e15a5f4.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/5/9/csm_UM-Ket_CIMG5312-800x600_8bc6ec89a0.jpg)

![[Translate to Englisch:] UM-Ket](/fileadmin/_processed_/7/1/csm_UM-Ket_20150925_085252-800x600_652b8862df.jpg)