Energy-efficient and flexible filling and packaging of up to 110 bags per minute.

UM100/3.

The ULF-Tec UM100/3 is the well thought out result of the experiences and developments of the past years. This involves a modular packaging line with simple and cost-effective production implementation that pays off, particularly with more complex processes. Its versatility, energy-efficient way of working and the simple maintenance options make the UM100/3 the perfect-fit solution for demanding users. It also offers impressive Made in Germany quality.

Products and Fields of Application

- Filling of dry products (cereals, sugar, flour, pasta, animal feed, etc.)

- Bags for coffee pads (large quantities or stacked), biscuits, confectionery

- Machines for pre-fabricated bags

Types of Bag and Packaging

- Sealable stand-up bags

- Suitable for paper packaging and plastic packaging

- Other materials on request

Options and equipment

- Extended bag magazine (max. 2 m, runtime of approx. 35 m without refilling of the bag)

- Data capture systems for production and downtimes

- Film group packers

- Paper packers

- Checkweighers

- Metal detectors

- Modem for remote maintenance

- Maintenance agreements

- Forming trolley for storing a forming set

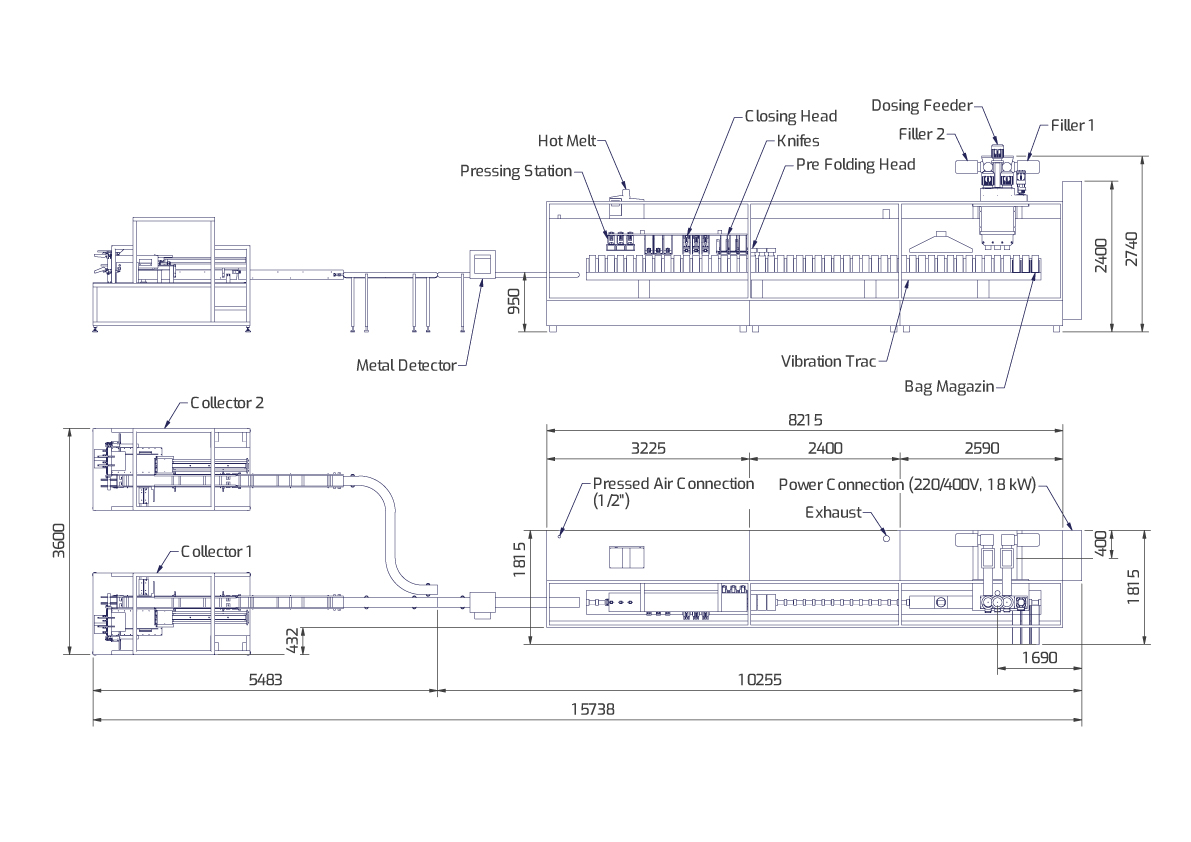

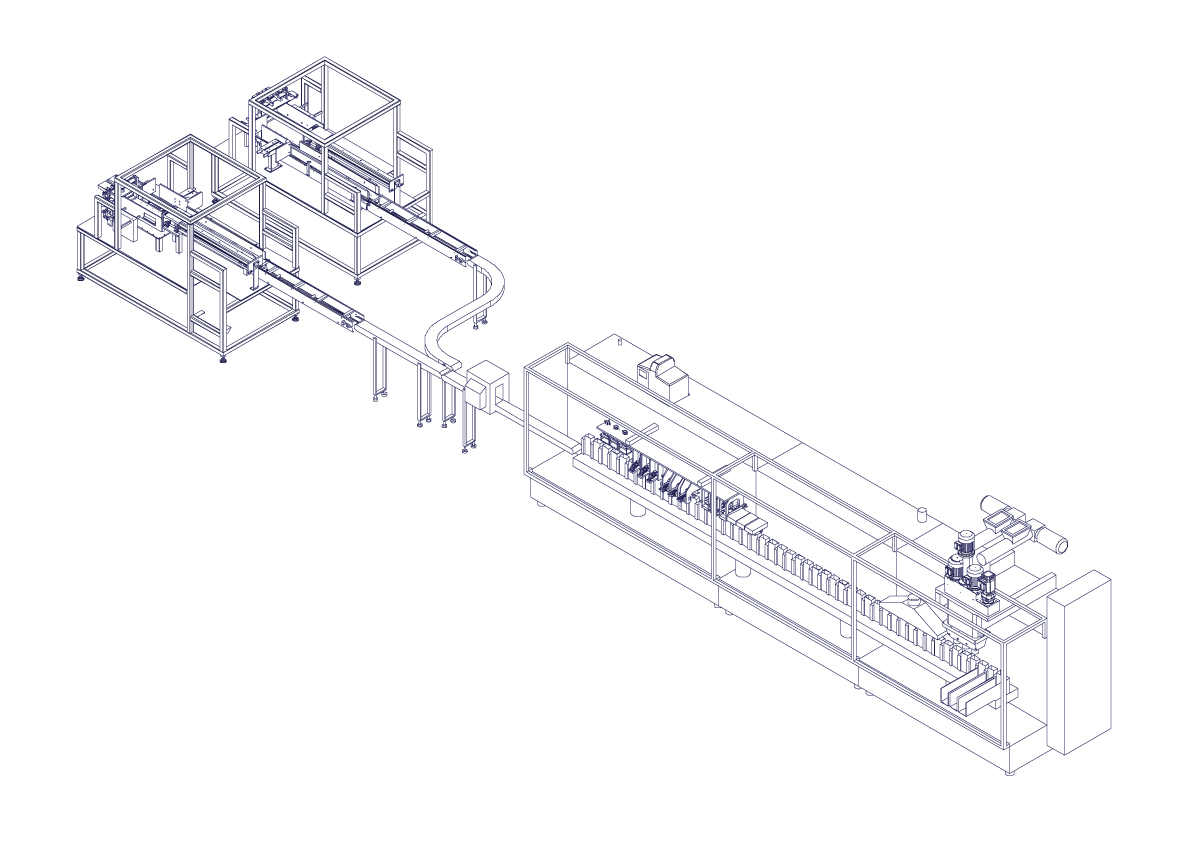

Basic construction

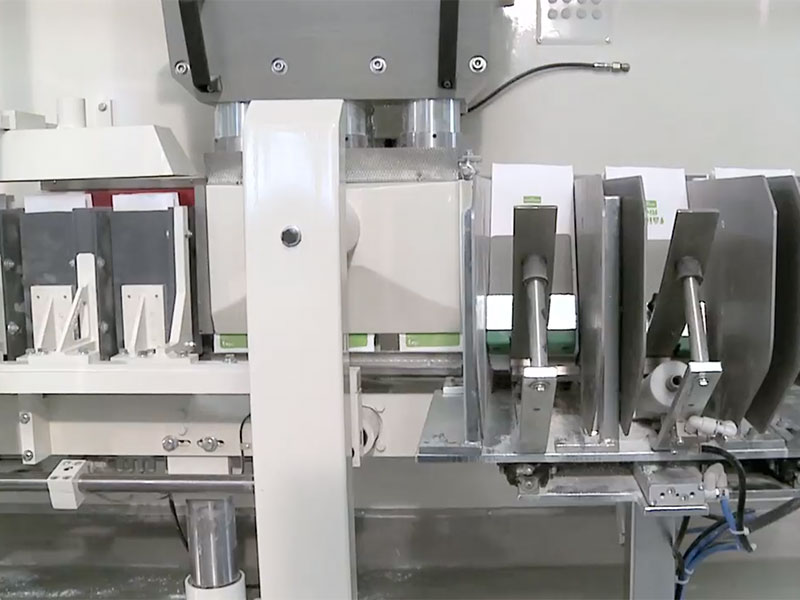

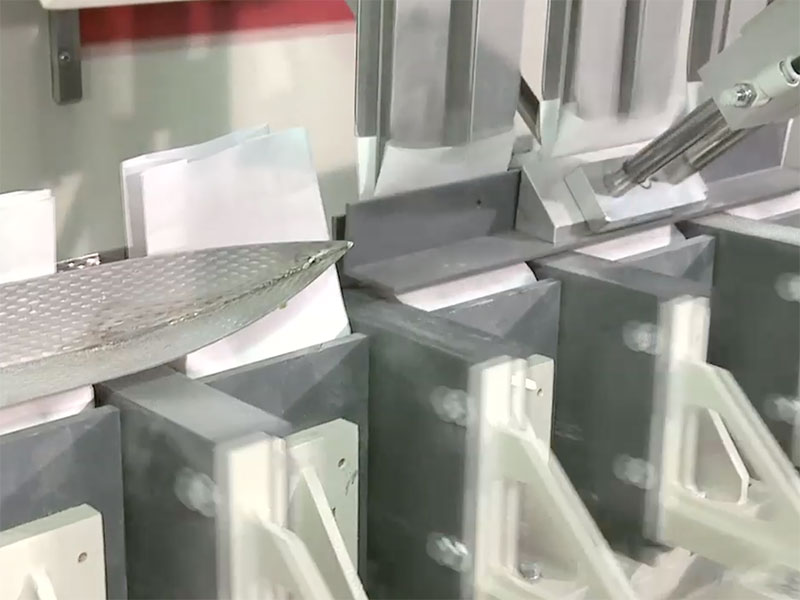

The UM100/3 is built onto a torsion-resistant base frame. Attached to this frame are the pneumatically powered cylinders for the bag transport system and the control equipment. The transport system offers user-friendly operation and can be adjusted effortlessly to various bag widths. Various package sizes can also be handled with ease, as can various materials. Cutting and creasing stations ensure a clean cut with low wear, while the custom-adjustable vibrating section ensures the correct height. Any contamination is identified very effectively by the integrated metal detectors.

The UM100/3 can be equipped with various processing stations and therefore adapted perfectly to customer-specific requirements. These include, for example, the simple folding of bag top edges (with and without securing), fitting of the bags with sheet metal closures or even attaching resealable closures or customised labels and markings. A points system and preliminary collector guide products towards transport packaging.

The machine is built with high quality, it is robust and it is therefore long-lasting. The machine components can all be reused in the event of subsequent technical restructuring. Virtually no maintenance or optimisation are required. Should spare parts be needed, these can be provided quickly and reliably. The control technology comes from Siemens and guarantees the best possible electronic reliability.

Operation

The UM100/3 is operated via a control panel with a 12-inch touch screen. Multiple password-protected operating levels ensures different and custom-protected intervention options. The system's individual functions, such as the scale check, can be called up using user-friendly menu navigation and set to the product or packaging type required. The control unit is accommodated in a separate control cabinet. A remote maintenance module also ensures the correct operation as well as the analysis of production data.

![[Translate to Englisch:] UM100/3](/fileadmin/redaktion/Content-Detailseiten/UM100/UM-100R_Folienpacker-1-bearb.jpg)

![[Translate to Englisch:] UM100/3](/fileadmin/redaktion/Content-Detailseiten/UM100/UM-100R_Folienpacker-3-bearb.jpg)